Currently two- and three-bed PSA ethanol dehydration processes are common in the industry. Optimal design and operation of molecular sieve gas dehydration unitsPart 1.

Molecular Sieve Desiccant Desiccant Supplier Manufacturer

A three-angstrom molecular sieve3A Molecular Sieve is developed particularly to dehydrate ethanol and has crystal pore holes measuring roughly three angstroms in diameter.

. Many of the worlds ethanol plants have been designed to use Zeochem molecular sieves. Water and ethanol form an azeotrope that limits how much water can be extracted by conventional distillation. Distillation can only remove water to approximately 5 of the total composition.

This molecular sieve is designed for high water content in the feed stream elevated temperatures and quick cycling all factors inherent in the ethanol drying processes. The 3A molecular sieve process out performs distillation at a fraction of the cost. Im studying ethanol-water separation by using molecular sieve adsorption pressure swing adsorption.

Zeochems proprietary manufacturing process provides the adsorbent superior strength and long service life avoiding costly sieve change outs and the resulting downtime. HYD03C is a molecular sieve that is specifically designed for Ethanol Dehydration Units and differs from standard molecular sieves by offering an advantageous balance of crush strength adsorption capacity and minimal co-adsorption properties. As the vapors pass the sieve bed in the very first step water gets adsorbed by the pores of the adsorbent structure.

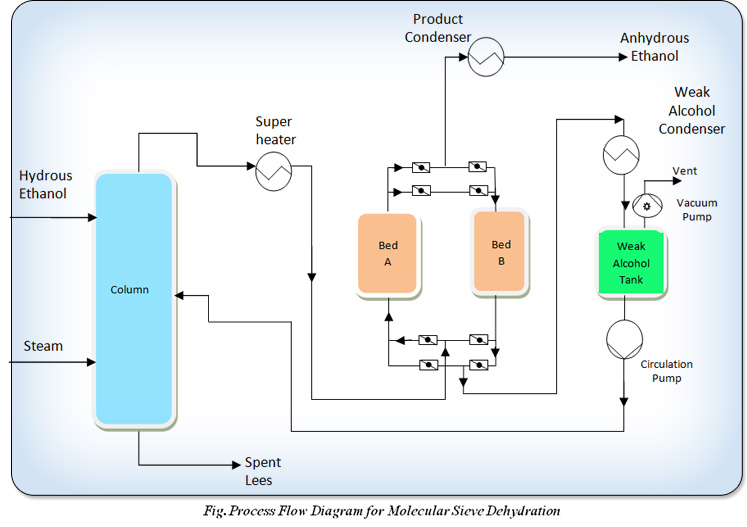

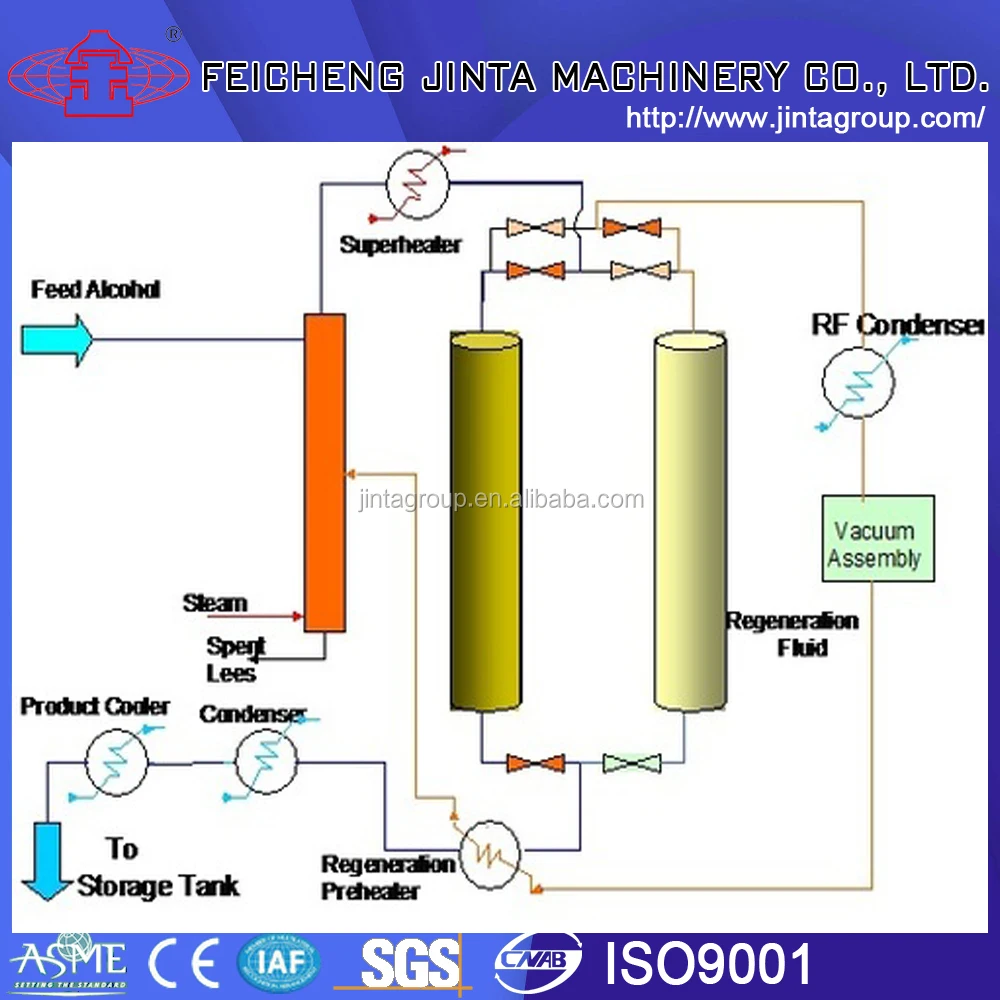

These Piping and Instrumentation Diagrams PIDs represent the 190 Proof Superheater Molecular Sieve Unit MSU and Condenser and Vacuum System respectively. This sieve is ideal for ethanol production because water molecules measure about 28 angstroms while ethanol molecules are about 36 angstroms. On contrary molecular sieves are able to concentrate ethanol to completely anhydrous state but finds economical acceptance for short span of 939980 ww ethanol.

The further purification of ethanol up to 9980 is done by dehydration using pressure swing system which includes molecular sieve 3A EDG as adsorbents. No moving parts or additional components required to operate. The Vogelbusch molecular sieve system allows the dehydration of ethanol past 95 purity.

Pure ethanol 996 comes out the bottom of the dehy column ethanol-water-cyclohexane comes out the top is decanted and ethanol-water returned to rectifying column and cyclohexane back to dehydration column. 855864 SEPARATION OF ETHANOLWATER MIXTURES USING MOLECULAR SIEVES 857 The main conclusion of these results is that the best type of molecular sieve that can be used for drying of ethanolwater mixtures type 3A. Molecular sieve consists of tiny zeolite crystals made of sodium aluminum silicate blended in a clay binder and formed into spherical ceramic beads.

Zeochems Z3-03 is the product of choice for use in the ethanol dehydration market providing excellent performance and long life. Thermal Kinetics Engineering PLLC TKE has designed the ethanol dehydration system configuration presented in drawings PD-1001 PD-1002 and PD-1003. In lieu of this feel free to speak directly to a Wintek engineer at 973 252-8200.

The adsorption of ethanol on 3A zeolite in the ethanol dehydration studies is usually neglected. Considering water molecules are approximately 28 angstroms in diameter and ethanol molecules are about 36 angstroms in diameter this sieve is suitable for ethanol synthesis. Ethanol product typically 99.

Selecting molecular sieve will be presented. Ethanol can only be dried to an azeotropic point of 956 purity by traditional distillation. This occurs due to polar attraction.

PSA technology is the preferred and industrially. Trans IChemE Part A Chemical Engineering Research and Design 2004 82A7. I have to create my own model in Aspen Custom.

Mokhatab Gas Processing Consultant Halifax Nova Scotia Canada. Recently the bioethanol dehydration has been studied for concentrations of 510 wt of ethanol from the fermentation step by extractive and azeotropic distillation in dividing-wall columns that are able to concentrate and dehydrate bioethanol in a single unit These sequences were optimized using sequential quadratic. The Up-flow design allows for longer residency times assuring complete water remediation.

Molecular sieve dehydration of ethanol uses a specialized molecular sieve to remove the water from the distillationrectification of ethanol and water. Please populate the following form to facilitate system design. This dehy column simply adds say cyclohexane to break the azeotrope.

Complete dehydration by. Ad Remove Moisture In Air-Drying Systems And A Variety Of Applications. It removes water from the ethanolwater vapor mixture that exits the rectification column to gain a dehydrated product.

The process of adsorption continues until the possible water adsorption from these vapors gets completed or molecular sieve gets saturated. The very precise pore size of molecular sieves enables them to select and remove. Inquiry for Dehydration System.

The CRCfilters EDH-2545 is a high efficiency ethanol drying system for use with 3A molecular sieve. General Design Consideration Natural gas either from natural production or storage reservoirs is saturated with water. In the ethanol dehydration process the hydrated ethanol vapors are passed through the molecular sieve bed.

HYD03C 3A Molecular Sieve. A three-angstrom 3A molecular sieve such as the EthaDry offered by Hengye Inc is specifically designed to dehydrate ethanol with crystal pore openings measuring about three angstroms in diameter. Using multi-pressure distillation the ethanol and water mixtures are progressively closer to the azeotropic ratio of 95545.

In the ethanol PSA process the water is removed with appropriately sized molecular sieve adsorbent. Our Z3-03 molecular sieve is designed for targeting only water molecules in the feed stream while minimizing the co-adsorption of. The application of the molecular sieve dehydration theory with examples will make the design easier to understand for a molecular sieve dehydration unit.

The internal surfaces of the molecular sieve adsorbs more of the water. Herold Contributing Writer Amsterdam The Netherlands. Molecular sieve technology is widely used for the simultaneous removal of water and mercaptans from both gas and liquid feed streams.

Ethanol Dehydration Grade Molecular Sieve mSORB 3A EDG is specifically designed for the dehydration of fuel grade ethanol. The bed of sieve beads adsorbs water molecules from the liquid as it passes through it. This Liquid Phase MSDU Design passes a liquid stream of wet alcohol or solvent through a column filled with molecular sieve beads in a process known as molecular sieve dehydration.

After that point mSORB EDG selectively adsorbs the water from the solution to produce anhydrous ethanol with less than 05 water.

Molecular Sieve Dehydration Vogelbusch Biocommodities

Figure 3 From Comparison Of The Main Ethanol Dehydration Technologies Through Process Simulation Semantic Scholar

Optimizing The Efficiency Of Anhydrous Ethanol Purification Via Regenerable Molecular Sieve Sciencedirect

Fenix Process Technologies Pvt Ltd Specializes In Process Engineering Equipments Turnkey Systems

Schematic Diagram For Beds Used In Ethanol Dehydration By Molecular Download Scientific Diagram

Molecular Sieve Dehydration Vogelbusch Biocommodities

Dehydration Equipment For Pure Alcohol Ethanol Pure 99 8 99 9 Buy Dehydration Section Molecular Sieve 99 8 Physical Method Dehydrator Equipment Plant Purify Plantation Alcohol Making Dehydration Food Equipment Product On Alibaba Com

Schematic Diagram For Beds Used In Ethanol Dehydration By Molecular Download Scientific Diagram

0 comments

Post a Comment