Back pitch p b 3. Butt joints Lap joints.

Design Of Riveted Joint Failures May 2020

Rivets Riveted Joints Ppt Download Familiaris occurring as a wide variety of breeds many of which are traditionally used for hunting herding drawing sleds and other tasks and are kept as pets.

. Design data hand book by Mahadevanhttpsamznto2v49HXYUnit _11. The permissible stresses are. This type of rivets is shown in the figure.

PowerPoint PPT presentation free to view. Many times such joints are required to be leak proof so that gas contained inside is not allowed to escape. 116 to 316 thick metal.

Its diameter is 16D and its height is 07D. These joints are so strong that in the case of boilers or girders of bridges plates joined by riveting cannot be separated without damaging the rivets. Riveted joints are more crack resistant than welded joints in ship hulls.

Otherwise is obtained by equating crushing strength to the shear strength of the joint. A Misguided Idea The truth behind the universal but flawed catchphrase for creativity. Up to 5 cash back Welding is a process by which permanent joints are made.

The joints of this rivet are very strong. Pulleys and belts Chains and sprockets Seals and Circlip Shaft Couplings Riveted Joints Caulking and. Brazing Rod Spelter Whole of joint area is heated and it is the heated joint that melts the Spelter.

In engineering practice it is often required that two sheets or plates are joined together and carry the load in such ways that the joint is loaded. The PowerPoint PPT presentation. Designs of welded assemblies can be easily and economically used to meet the changing product requirements.

Single or multiple rows of rivets are used to give strength. Types of riveted joints and joint efficiency. Since welding is used extensively efforts are on to refine it.

Rivets can fail by shearing through one cross-section. Design of column according ACI codes 1. Riveted Joints Mechanical Joints In manufacturing industries joining of two or.

Shearing of the rivets 2. When thickness of the plate is more than 8 mm Unwins formula is used t d 6. The riveted joints are widely used for joining light metals.

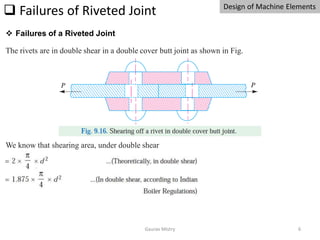

DESIGN OF RIVETED JOINTS. Margin or marginal pitch m Failures of a Riveted Joint 1. Up to 5 cash back Riveted joints are used to connect parts when welding facilities are unavailable.

Lap-joints and butt-joints Fig. The rivets are used for permanent fastening. The design parameters in a riveted joints are.

Rivets are inserted on the overlapping portion. In a double riveted zigzag joint this implies. Design of Machine Elements.

Design of rivet joints. τ 100 MPa. Riveted Joints Caulking and Fullering Types of rivets Self Study.

½ Inch metal and up can be welded using a double V or. The rivets are inserted in the overlapped region. It is process of joining two metal parts by fusing them.

In lap joints the components to be joined overlap each other while for butt joints an additional piece of material is used to bridge the two components to be joined which are butted up against each other. PowerPoint PPT presentation. 532 Fatigue Strength of Bolted Butt Joints 118 54 Design Recommendations 126 541 Introduction 126 542 Design RecommendationsFasteners 128 543 Design RecommendationsConnected Material 138 544 Design Recommendations for Bearing Stresses 143 6.

Materials Technology - The methods by which materials are joined permanent. Even now as the strength of a welded joint depends. In this type of riveting the plates to be joined is kept in alignment butting touching without forming an overlap.

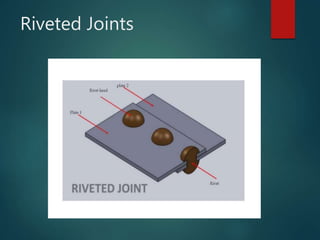

Depending on the how riveted plates are placed the riveting classified mainly into two i Lap joint ii Butt joint. The function of rivets in a joint is to make a connection that has. Butt joint a Butt joint with single cover butt joint b Butt joint with double cover butt joint Important Terms Used in Riveted Joints 1.

In lap joint plates overlapped each other. They are strong and resistant to leaks and hence used extensively. A double riveted double cover butt joint in plates 20 mm thick is made with 25 mm diameter rivets at 100 mm pitch.

σc 150 MPa Find the efficiency of joint taking the strength of the rivet in double shear as twice than that of single shear. 36 MODES OF FAILURE OF A RIVETED JOINT A riveted joint may fail in several ways but the failure occurs as soon as failure takes place in any one mode. Welded assemblies are leak proof as compared with riveted assemblies.

RIVETED JOINT is the property of its rightful owner. A riveted joint is easily conceived. A rivet is a short cylindrical bar with or head integral to it.

Rivets with this kind of heads are used most of all. That is why it is widely used in bridges made of iron material. The plates that are to be joined are brought face to face such that an overlap exists as shown in fig.

TYPES OF RIVETED JOINTS. Rivets are used to permanently fasten two or more plates or pieces of a metal. 38 to ½ inch metal can welded using a single V or U joint.

Some interfacial friction damping effects also occur in welded joints but welded joints are much stiffer than the bolted joints. Crushing of the plate or rivets 3. Such joints made.

Design of Eccentric Loaded Riveted Joints. σt 120 MPa. Rapid development in the welding techniques has replaced riveted joints.

The cylindrical portion of the rivet is called shank or body and lower portion of shank is known as tail. Types of Welded Joints Butt joint Corner joint Edge joint Lap joint T joint Square Butt Joints Used to butt weld light sheet metal. Beveled Butt Joints Used to butt weld heavier pieces of metal together.

Manage the extension of cracks in structure through the application of the principles of fracture mechanics. Truss-Type Connections 148 61 Introduction 148. D p and m Diameter of the hole d.

Following is the description of modes of failures of a riveted joint. The head is of a semi-circle in shape. Snap head or cup head rivets.

There are two main types of riveted joint. A problem of designing of a riveted joint involves determinations of p p b p d m t t c and d depending upon type of the joint. View Riveted Joints 1pptx from MECHANICAL ENGINEERING 1101152008 at Sikkim Manipal University.

Riveted joints are mainly of two types 1. Introduction A welded joint can be used as a substitute for a riveted jointit is l A welded structure can be used as an alternative method for casting or forging.

Design Of Riveted Joint Failures May 2020

Design Of Riveted Joints Boiler Joints

0 comments

Post a Comment